If you have questions or suggestions, please leave us a message, we will reply you as soon as we can!

Contact usMost technical ceramics are exclusively inert and non-toxic, which means they are largely non-polluting. For example, aluminum oxide (alumina) powder is categorized as safe for use in cosmetic products, including antiperspirant deodorant, indicating minimal-to-no-risk of bioaccumulation, cytotoxicity, immunotoxicity, or reproductive toxicity.

Meanwhile, zirconia is one of the most frequently used dental biomaterials around the world. The astounding biocompatibility of such materials is a symptom of their intrinsic inertness, which also accounts for their general lack of decomposition over time.

Recyclability is another key factor of sustainability; how effectively materials can be reused and recycled. As ceramic materials do not deteriorate naturally, they do not simply decompose into raw materials for reformation. However, once aggregated, there are novel applications on hand for so-called ceramic waste.

A number of engineers have transformed this shortcoming into a potential sustainable solution, utilizing recycled crushed ceramic rubble (RCCR) to stabilize expansive soil and advance progress in geotechnical engineering.

Studies have demonstrated the technical practicability of RCCR for stabilizing expansive, highly expansive soils (HES). Therefore, beyond its component life cycle, aggregated ceramic waste continues to contribute to a healthy environment.

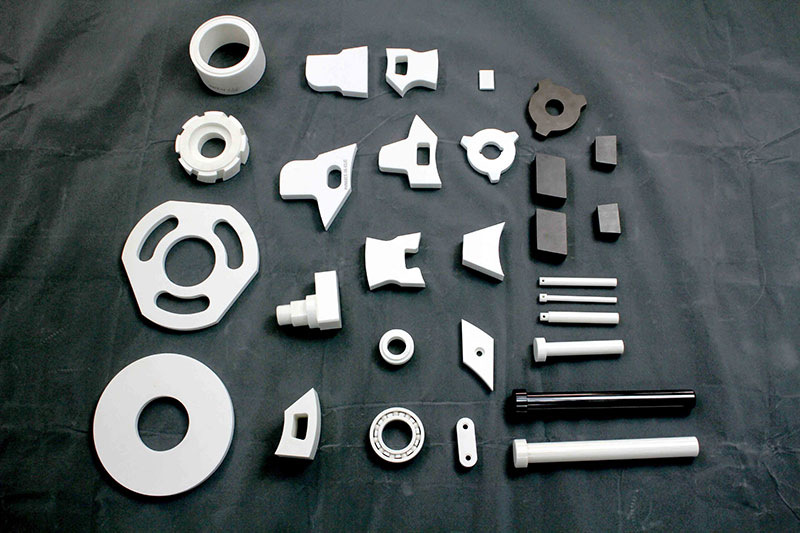

Technical ceramics are replacing heavy duty metallic alloys and even refractories in several challenging applications and industries, establishing ceramics as a cornerstone in the production of advanced engineering materials.

This derives from their excellent all-round thermomechanical properties but can also be associated with gradual improvements in the design and development of ceramics and ceramic manufacturing.

So, what effect does this shift towards high performance, specialist material solutions have on the social responsibilities of corporations and sustainability initiatives?

Manufacturing advanced ceramics is an intricate multi-step process centered on the consolidation and sintering of raw mineralogical feedstocks.

Regardless of the type of ceramic (oxide or non-oxide) or the shape, size, structure, or complexity of the completed part, it is the densification stage of production that reveals the exceptional thermomechanical properties of technical ceramic materials.

However, it is also the most energy-intensive link in the manufacturing chain of advanced ceramics. Therefore, it is difficult to reconcile ceramic manufacturing from an environmental perspective due to the power-hungry nature of sintering processes.

So, it is worth considering key ceramic manufacturing processes to see whether they could be regarded as environmentally friendly.

The green forming stage of ceramics manufacturing takes place when raw powders are amalgamated into a ‘green body’ using applied pressure.

Techniques that are common include uniaxial pressing, compacting feedstocks into a rigid shape using a tool steel die; isostatic pressing, where spray-dried powder in a polyurethane/rubber bag is exposed to isostatic pressure; extrusion, forcing a plasticized paste-like mixture through an orifice; and slip casting, which utilizes an aqueous slip and a porous mold.

It is hard to assess an overall ecological footprint due to the diversity of forming processes. For instance, applied pressures in uniaxial or isostatic pressing can range from 20—700 MPa, with high compaction pressures generally translating to higher green compact strength.

Mechanical green forming methods such as these typically depend on moderately energy-intensive processes such as electrically derived pneumatic or hydraulic pressures – yet, these processes are gradually improving in efficiency. High volume commercial potteries serve as an example where pressure is a chosen application.

To reduce casting time and improve throughput, slip is pushed into porous molds, speeding up the natural capillary action necessary for slip casting and reducing casting times by a factor of 10. In this case, traditional slip casting would be commercially impracticable.

However, the majority of ceramic forming processes are not thermal in nature —with the notable exception of hot isostatic pressing (HIP)— so the forming stage is relatively ecological.

After consolidation, the green body is fired at extreme temperatures via either solid-state or liquid-phase sintering.

While potteries and ceramic construction material manufacturers rely heavily on traditional gas-powered furnaces, technical ceramic sintering very rarely takes place in open flames because of the ceramic’s sensitivity to atmospheric conditions and the necessity for precision temperature control.

Instead, extremely high temperatures requisite to densification are produced utilizing electrical resistance of metallic or composite heating elements.

Utilizing renewable energy sources such as hydroelectricity, solar and wind means the sintering processes could have a low environmental impact in contrast to other manufacturing processes.

Here, an opportunity is presented for technical ceramics manufacturing to embrace the green technology revolution, and by doing so, significantly reduce the environmental costs affiliated with continuous material production.

Parallel to the expansion of the environmental engineering sector is the more familiar market of clean energy. Today, there is a broad consensus that a global movement towards clean energy is crucial to how we can preserve the natural systemic balance of the planet’s ecosystems.

This means significantly reducing greenhouse gas emissions by embracing hybrid and electric vehicles while obtaining energy from renewable sources like wind and solar.

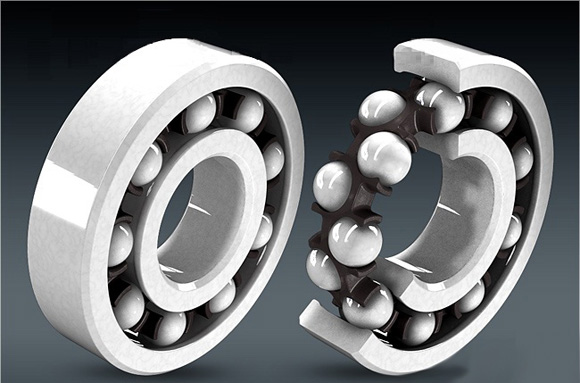

Advanced ceramics continuously play a significant role in clean energy production, from specialized piezoelectric systems for solar exchangers to solid oxide fuel cells (SOFCs) and high temperature roller bearings in high efficiency wind turbines.

Innovative transformations in additive manufacturing of technical materials facilitate the manufacture of more complex, long-lasting systems for hyper-efficiency energy conversion systems. For instance, 3D printed microturbines and impellers made up of silicon nitride (Si3N4) may offer novel solutions for hybrid vehicle motor recuperation.

To discover how advanced ceramics could benefit your sustainability initiatives, please contact sales@johncera.com for more information.

Article source: Network

[Disclaimer] The article is the independent opinion of the author and does not represent the position of Johncera. Please contact Johncera within 30 days after the publication of this article to delete or discuss copyright use.